Power Transfer Switch Guide Manual and Automatic Options Explained

Explore reliable power transfer switches for home generators featuring manual and automatic options ensuring safe seamless backup power.

Read More

In modern homes, commercial buildings, and industrial facilities, sensitive electronics and control systems are constantly exposed to short, high‑energy spikes in voltage known as surges. A surge protective device (SPD) is a dedicated protective component that limits these transient overvoltages and diverts the associated surge current away from equipment and safely to earth. By clamping the surge to a safer level, an SPD helps prevent insulation breakdown, premature equipment failure, and unexpected downtime in the electrical installation.

Unlike fuses or circuit breakers, a surge protective device is not designed to respond to overloads or short circuits that last for many cycles; instead it reacts within microseconds to very brief but potentially destructive surges caused by lightning, switching events, or network disturbances. For beginners, understanding what an SPD does, where it should be installed, and how to read its key ratings is the first step to designing a robust low‑voltage protection strategy. This guide explains the basic principles in clear language and links theory directly to real product examples you can use in low‑voltage distribution boards.

A surge protective device is a component of the electrical installation that limits transient overvoltage of atmospheric or switching origin and discharges surge currents to earth. In normal operation, the SPD remains in a high‑impedance “standby” state and only becomes conductive when the voltage exceeds a defined threshold, thereby protecting the connected system against dangerous overvoltage.

Power surges are very short‑duration increases in voltage that typically last from a few microseconds up to a few milliseconds, but their peak values can be several times higher than the nominal system voltage. External surges are often caused by lightning strikes or utility switching events, while internal surges can come from large motors, capacitor banks, or other equipment being switched on and off inside the installation. Even though each transient is brief, repeated exposure can erode insulation, stress semiconductor devices, and lead to unexplained failures of power supplies, controllers, and communication equipment over time.

An SPD is typically connected in parallel with the load so that, under normal conditions, almost no current flows through it and the system voltage is applied directly to the equipment. When a surge raises the voltage above the device’s protection level, its internal non‑linear components—often metal oxide varistors, gas discharge tubes, or a combination—switch rapidly to a low‑impedance state and divert the surge current to earth or back to the supply, limiting the voltage seen by the load. After the transient has passed, the surge protective device returns to its high‑impedance state, allowing the system to continue operating with minimal interruption.

Product spotlight – basic AC SPD

For a practical example of a modular AC surge protective device suitable for small low‑voltage boards, you can refer to the G2010MT Type 2 surge protective device 10kA, which offers compact DIN‑rail mounting and is designed for AC surge protection in distribution panels.

International and manufacturer guidance groups low‑voltage SPDs into Type 1, Type 2, and Type 3, based primarily on their intended installation location and the surge energy they are designed to handle. In practice these types work together in a coordinated way to provide cascaded protection from the service entrance down to sensitive point‑of‑use equipment.

Type 1 surge protective devices are installed at the origin of the electrical installation, typically between the service transformer secondary and the line side of the main service disconnect or in the main distribution board. Their purpose is to withstand and divert high‑energy surges, including partial lightning currents associated with direct or nearby strikes, and they are usually characterized by a 10/350 µs current waveform in standards. In buildings where the risk assessment shows significant exposure to lightning, Type 1 SPDs are the first line of defense for protecting the insulation and primary equipment of the installation.

A practical example is the G2015MT Type 1 surge protective device for main distribution, which is designed for installation in main switchboards to handle lightning‑related surges on AC power lines.

(Insert G2015MT product image here and link it to the product URL above.)

Type 2 SPDs are installed on the load side of the main service disconnect, typically at sub‑distribution boards or main distribution panels in residential, commercial, and industrial systems. Their primary function is to protect downstream circuits and sensitive electronics against residual surges that pass through the Type 1 device, as well as switching transients generated inside the building. In many low‑voltage installations that do not face high lightning exposure, a correctly selected Type 2 surge protective device provides the main level of protection for everyday operation.

For example, the G2040DZ Type 2 AC surge protective device 40kA offers a 40 kA rating suitable for typical low‑voltage distribution boards in small commercial or residential applications and is designed as a DIN‑rail surge arrester for power distribution protection.

(Insert G2040DZ product image here and link it to the product URL above.)

Type 3 SPDs are point‑of‑use devices installed close to sensitive loads such as IT equipment, AV systems, medical devices, and industrial controllers. They are designed for lower surge currents and provide fine protection by clamping any remaining overvoltages that slip past upstream Type 1 and Type 2 devices, often integrated into power strips, socket outlets, or equipment‑specific protectors. A coordinated approach that combines Type 1 at the service entrance, Type 2 at distribution boards, and Type 3 at the point of use is widely recommended for critical installations with sensitive electronics and high availability requirements.

Choosing the right surge protective device is not only about picking the correct type number; it also requires understanding key electrical ratings and matching them to the system characteristics and risk level. Important SPD parameters include maximum continuous operating voltage, nominal discharge current, maximum discharge current, voltage protection level, and short‑circuit withstand capability in coordination with upstream protective devices.

The maximum continuous operating voltage (Uc) of an SPD must be equal to or higher than the highest RMS voltage that can appear continuously at its terminals in the system, including tolerances and possible neutral disconnections. For example, in a 230/400 V TN‑S system, SPDs selected for phase‑to‑neutral and phase‑to‑earth modes must have Uc values appropriate to those voltages, and the connection scheme must match the earthing system (TN, TT, or IT) recommended by standards and manufacturers. Using an SPD with an undersized Uc can cause premature ageing or continuous leakage currents, while selecting an excessively high Uc may reduce the level of protection provided to the equipment by allowing higher clamping voltages.

Series such as the G20XXMT Type 2 modular surge protective device range provide multiple voltage variants and pole configurations for common low‑voltage systems, allowing designers to align Uc and connection type with the actual installation topology. This makes it easier to standardize on one SPD family across several panel designs while still respecting the specific earthing system and nominal voltage of each project.

The nominal discharge current (In) and maximum discharge current (Imax), usually expressed in kiloamperes (kA), indicate the surge energy the device can handle during standardized test waveforms. Type 1 SPDs are tested with high‑energy 10/350 µs waveforms representing lightning currents, while Type 2 devices are tested with 8/20 µs waveforms typical of switching and residual surges, and their kA ratings help compare robustness across products. For main distribution boards in commercial or industrial facilities, designers often select Type 2 SPDs with higher kA values to provide a safety margin for repeated surge events over the product’s lifetime and to align with the expected lightning and switching environment.

Another key parameter is the voltage protection level (Up), which is the maximum voltage that appears at the SPD terminals during a standardized surge; equipment with very sensitive electronics benefits from SPDs with lower Up values to keep the stress below insulation and component limits. Coordinating these ratings with the insulation withstand of cables, switchgear, and connected devices ensures the surge protective device will clamp surges below damaging levels without unnecessary nuisance operations or overstressing the SPD itself.

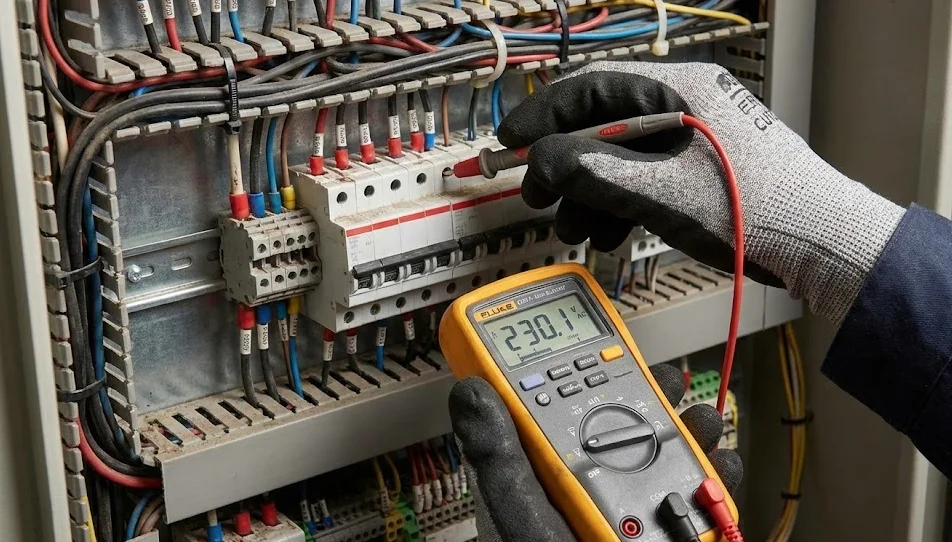

Correct installation of surge protective devices is just as important as choosing the right type and rating, because poor wiring practices can increase the effective protection voltage and reduce the benefit of the device. Standards and manufacturer guides emphasize locating SPDs as close as possible to the protected equipment or distribution busbars and minimizing connection lead lengths to keep inductive voltage drops under control.

Type 1 SPDs are generally installed in the main distribution board or at the service entrance, with connections to all live conductors and the main earthing terminal according to the earthing system and applicable regulations. Type 2 devices are then placed in downstream distribution boards, especially where circuits supply sensitive or mission‑critical loads, so that residual surges are clamped before reaching these circuits and their equipment. In communication and control systems, dedicated SPDs are installed on signal and data lines, such as Ethernet, PoE, or control loops, to protect both power and communication channels from transient overvoltages that can travel along cables.

For example, the G20POE integrated power and network surge protector combines protection for both power and Ethernet lines, making it suitable for IP cameras, access points, or other network devices exposed to outdoor lightning and switching surges. When used together with panel‑mounted SPDs on the AC side, such integrated devices help create a complete protection chain from the main board to the endpoint equipment.

One of the most critical mistakes is using long, looped connection leads between the SPD and the distribution busbars or earthing bar, because the inductive voltage drop on these leads during a surge adds directly to the protection level and can negate much of the benefit of the device. Good practice is to keep all SPD conductors as short and straight as possible, prefer V‑shaped or “bridged” connections, and follow the manufacturer’s recommended maximum lead length, often a few tens of centimeters at most. Another frequent error is failing to coordinate the SPD with upstream overcurrent protection; if the back‑up fuse or breaker is not properly rated, it may trip or fail during a surge event, leaving the installation unprotected or causing unnecessary outages.

Environmental and mechanical factors should also be considered: SPDs must be installed in enclosures with appropriate IP ratings, ambient temperature limits, and clearance distances to other components, especially in dusty, humid, or corrosive industrial environments. Regular inspection and maintenance, including checking status indicators and replacing cartridges where applicable, help ensure that the surge protective device continues to perform as intended throughout its service life and that failed modules are not left in service unnoticed.

In many regions, modern wiring rules and standards treat surge protection as mandatory or strongly recommended whenever the consequences of a surge—such as loss of human life, interruption of public services, or large economic losses—are considered significant. Buildings with extensive electronics, automation, data networks, or rooftop solar installations are particularly vulnerable to surges from both external lightning and internal switching, making SPDs a cost‑effective layer of risk reduction compared to equipment replacement and downtime.

Even in smaller residential installations, the growing number of sensitive devices such as smart home controllers, LED lighting drivers, heat pumps, and EV chargers means that a relatively modest investment in a coordinated surge protective device system can prevent expensive failures and inconvenient outages. By combining appropriately selected Type 1 and Type 2 SPDs in the main and sub‑distribution boards, and adding Type 3 or dedicated signal‑line protectors for critical loads, designers can implement a layered defense that significantly improves the resilience and reliability of low‑voltage systems.

Q1. Is a surge protective device the same as a surge‑protected power strip?

A surge‑protected power strip is a form of Type 3 SPD intended for point‑of‑use protection, but a complete surge protection system also includes upstream Type 1 and Type 2 devices in the distribution boards to handle larger surges.

Q2. Do SPDs need maintenance or replacement?

Many SPDs use metal oxide varistor technology that gradually degrades with repeated surges, so visual indicators or remote contacts typically show end‑of‑life conditions, and cartridges or modules should then be replaced according to the manufacturer’s instructions.

Q3. Will an SPD protect against all power quality problems?

Surge protective devices are designed for transient overvoltages; they do not correct long‑term undervoltage, overvoltage, harmonics, or outages, which require other solutions such as voltage regulators, UPS systems, and proper coordination of protection devices.

Q4. Can I install an SPD myself?

For safety and compliance with local standards, SPDs in fixed wiring should be installed by qualified electricians who understand earthing systems, protective device coordination, and relevant regulations.