Type 2 Surge Protection Device Features Benefits and Installation Guide

Discover reliable Type 2 surge protection devices offering IEC 61643-11 compliance, high surge capacity, and advanced voltage clamping for electrical safety.

Read More

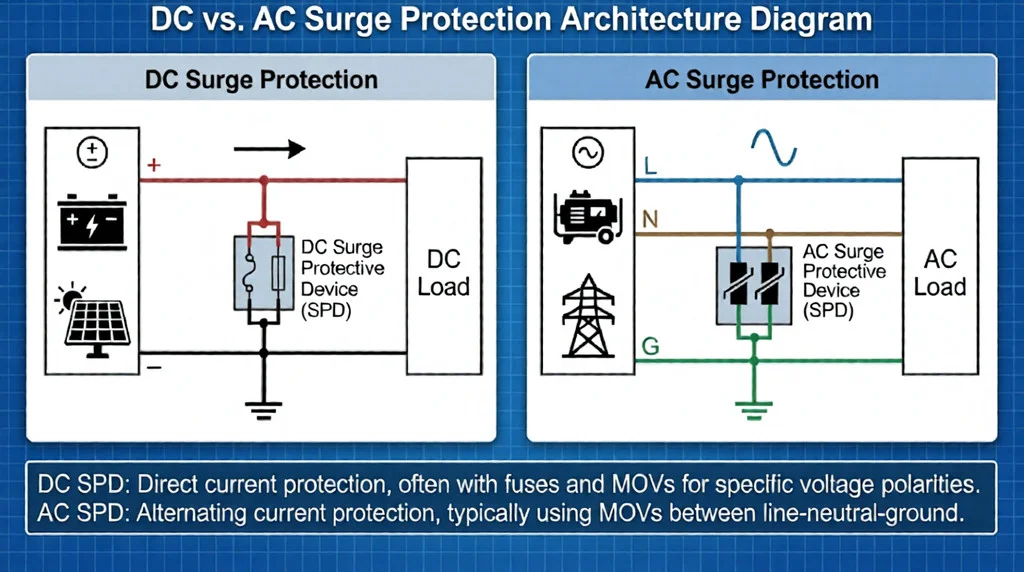

Understanding DC vs AC surge protection is now essential for every electrical engineer working with low‑voltage power distribution, PV systems, EV charging, and industrial control. In many real projects, engineers must combine AC surge protection devices at distribution boards with DC surge protection devices on PV strings, batteries, and DC buses; choosing incorrectly can lead to premature failure or unsafe operation. A simple example is pairing an AC Type 2 SPD such as the G2040DZ Type 2 AC surge protective device 40kA with a DC surge protection product like the G2040PV‑BC Type 1+2 PV surge protective device in a solar inverter system.

This article explains the key differences between DC vs AC surge protection, how surge waveforms and device construction change from one domain to the other, and what practical selection rules engineers should follow. It also walks through typical applications, from rooftop solar DC surge protection to AC surge protection for distribution switchboards and building services.

For electrical engineers, DC vs AC surge protection is more than a catalog choice; it directly impacts equipment reliability, insulation coordination, and compliance with standards. AC systems in buildings and industry have historically been the main focus of surge protection, but the rapid growth of PV arrays, battery energy storage, and DC microgrids means that DC surge protection is now equally important. If an engineer mistakenly applies an AC‑only SPD on a high‑voltage DC string, the device can overheat, fail to clear safely, or provide inadequate clamping.

Conversely, DC surge protection devices optimized for PV strings may not be mechanically or electrically suitable for AC distribution boards. Engineers must therefore treat DC vs AC surge protection as two related but distinct tasks: matching voltage and earthing conditions, matching waveform and duty, and matching mechanical form factor to the installation environment. Getting this right leads to fewer unexplained outages, longer equipment life, and easier project sign‑off.

Product spotlight – overview section

A common pattern in mixed systems is using G2040DZ Type 2 AC surge protective devices in AC distribution panels and G2015PV‑BC Type 1+2 PV surge protective devices on the DC side of solar inverters.

When comparing DC vs AC surge protection devices, engineers should first understand what they have in common and what must differ. In both cases, the SPD behaves as a non‑linear element connected in parallel with the protected circuit, switching from high impedance to low impedance when the voltage exceeds a threshold. However, the continuous operating voltage, insulation requirements, arc behavior, and failure modes differ significantly between DC and AC.

In AC surge protection, the alternating waveform naturally passes through zero, which helps extinguish arcs after a surge event. In DC surge protection, the absence of current zero crossing makes arc extinction more difficult, so internal components and protective coordination must be designed to cope with continuous stress. As a result, DC vs AC surge protection products may look similar externally but are not interchangeable.

The most fundamental difference between DC vs AC surge protection lies in the voltage and current waveforms. AC systems are defined by an RMS voltage and frequency, with the instantaneous voltage swinging sinusoidally above and below zero. Surge events on AC lines ride on top of this alternating waveform, and SPD ratings such as maximum continuous operating voltage (Uc) are related to the RMS value. In DC systems, the voltage is nominally constant, and SPDs must withstand a continuous, unidirectional electric field without the benefit of zero crossings.

From a surge waveform perspective, both DC and AC systems are exposed to 8/20 µs switching surges and 10/350 µs lightning surges, but the way these surges dissipate is different. In AC systems, upstream breakers and fuses can interrupt fault currents with the help of current zero; in DC systems, breakers, fuses, and DC surge protection must be sized and constructed to interrupt fault currents without a natural zero. This makes energy handling and thermal design especially important for DC vs AC surge protection, particularly on long PV strings or high‑voltage DC buses.

In both DC vs AC surge protection, common components include metal oxide varistors (MOVs), gas discharge tubes (GDTs), and combinations that form hybrid SPDs. MOV‑based designs are often favored for AC surge protection in distribution boards because they provide fast response and predictable clamping characteristics. GDTs and spark gaps can carry very high surge currents and are often used in Type 1 devices or in DC circuits where isolation at normal voltage is required.

For DC surge protection, internal construction must address continuous DC voltage stress and potential arc formation. This may involve longer creepage and clearance distances, additional thermal disconnects, or specific arrangements of MOVs and GDTs optimized for DC operation. Engineers comparing DC vs AC surge protection should therefore look beyond just the voltage rating and check whether the device is explicitly certified for DC or AC use, especially in safety‑critical or high‑power applications.

Product spotlight – core concepts section

The G2040MT modular Type 2 surge protective device 40kA illustrates a typical AC SPD design for low‑voltage panels, while PV‑rated devices like the G2040PV‑BC 12.5kA Type 1+2 PV surge protective device show construction tailored for DC surge protection on solar arrays.

product G2040MT

and G2040PV‑BC

Once the engineer understands the basic differences, the next task is applying practical selection rules for DC vs AC surge protection. On the AC side, selection typically starts with system voltage (e.g., 230/400 V), earthing system (TN, TT, IT), and surge environment. The SPD’s maximum continuous operating voltage, nominal discharge current, and voltage protection level must be coordinated with breaker ratings and equipment insulation.

On the DC side, selection rules for DC surge protection emphasize string voltage, polarity arrangement, and connection to earth or floating systems. For example, a 1000 V or 1500 V PV string requires a DC SPD specifically rated for that DC voltage with appropriate modes of protection (e.g., between positive and negative, and to earth where applicable). Engineers should never assume that an AC SPD with a similar RMS rating is valid for use in DC surge protection, because the continuous DC stress and arc behavior are very different.

In mixed AC/DC systems such as PV inverters or battery storage, engineers must treat DC vs AC surge protection as two separate problems: DC surge protection on the PV or battery side, and AC surge protection on the grid or load side. Each side of the converter or inverter needs its own appropriately rated SPD, properly coordinated with upstream fuses or breakers and the internal protection of the equipment.

Product spotlight – selection rules section

A typical selection for an AC panel might use G2040DZ Type 2 AC surge protective devices or G2050DZ 50kA Type 2 surge protective devices depending on the surge risk, while DC PV combiner boxes might use G2015PV‑BC Type 1+2 PV surge protective devices or other PV‑rated models.

(Insert product images here for G2040DZ, G2050DZ and G2015PV‑BC, each linked to its URL.)

Engineers encounter DC vs AC surge protection decisions in many modern applications. In rooftop PV systems, DC surge protection devices protect PV strings, combiner boxes, and inverters against lightning‑induced surges, while AC surge protection devices are installed at the building’s main distribution board to protect connected loads and grid interfaces. Utility‑scale solar farms extend these principles across many strings and combiner boxes, often using multiple coordinated stages of DC surge protection before the central inverter.

In industrial plants and commercial buildings, AC surge protection remains dominant in distribution boards, MCCs, and control panels feeding motors, drives, and HVAC systems. However, more processes now incorporate DC power supplies, battery racks, and DC busbars to support automation equipment or data centers. Each of these DC segments needs its own DC surge protection strategy, separate from the AC surge protection that guards the main incoming feeders. This layered approach allows engineers to tune DC vs AC surge protection independently based on the sensitivity and value of the equipment in each part of the installation.

EV charging infrastructure is another fast‑growing area where DC vs AC surge protection must be understood. AC chargers need AC surge protection on the supply side, while fast DC chargers, especially those connected to 400 V or 800 V battery systems, require DC surge protection tailored to their DC output circuits. In some architectures, the same charger station may combine AC and DC ports, making it essential to clearly separate and correctly specify surge protection devices for each side.

Good installation practices are just as important as correct device selection in DC vs AC surge protection. In AC panels, engineers and installers should minimize the length of SPD connection leads to phase, neutral and earth bars, avoiding loops and sharp bends that increase inductance and raise the effective protection level. Mounting SPDs close to the busbars and using short, straight links improves performance and reduces the risk of nuisance failures.

For DC surge protection, many of the same rules apply, but the higher DC voltages and lack of current zero crossing require extra attention to creepage, clearance, and wiring layout. Cables carrying DC surge currents should be routed to minimize coupling into nearby control or communication lines, and polarity must be carefully observed in PV and battery systems. When installing multiple SPDs in DC vs AC surge protection schemes, engineers should ensure that disconnection devices or fuses are accessible and that status indicators remain visible for inspection.

In both DC vs AC surge protection, periodic inspection is vital. Surge protective devices are sacrificial by design; after a certain number of surge events or one very severe surge, they may reach end‑of‑life and need replacement. Including SPD health checks in preventive maintenance schedules—especially for rooftop PV DC surge protection, exposed AC feeders, and mission‑critical loads—ensures that the intended level of protection is maintained throughout the installation’s life.

Q1. Can the same SPD be used for both DC and AC surge protection?

Only if the device is explicitly rated and certified for both DC and AC operation at the relevant voltages. Many SPDs are designed exclusively for AC or DC, and misapplying them can lead to overheating, inadequate clamping, or unsafe failure modes.

Q2. Why are PV surge protection devices usually rated for higher voltages than AC SPDs?

PV strings often operate at 600 V, 1000 V or 1500 V DC to reduce current and cable size, which is much higher than common 230/400 V AC distribution voltages. DC surge protection for these strings must therefore be rated for the full DC string voltage plus tolerances and designed to withstand continuous DC stress.

Q3. Is DC surge protection always needed on small rooftop PV systems?

The need for DC surge protection depends on local lightning risk, system layout, cable lengths, and applicable standards. In some low‑risk environments, AC surge protection at the main distribution board may be considered sufficient, but many standards and manufacturers strongly recommend or require DC SPDs on PV arrays, especially in exposed locations.

Q4. How should engineers document DC vs AC surge protection in project drawings?

Single‑line diagrams and panel schedules should clearly identify each SPD, its type (Type 1, Type 2, Type 3), its AC or DC rating, and its location in the system. This clarity helps during installation, inspection, and future maintenance, and reduces the risk of confusion between DC vs AC surge protection devices when replacements are needed.